↓

Egg production platform

Introduction

Total production platform product3770 ㎡, in whichDGrade purification area2000 ㎡, isolated and purified by fermentation and egg production2system art group. The platform is equippedManyA set of different specifications of full-hand fermentation system, full-hand liquid distribution system, purification system, fast freezing separation machine, full-hand washing, drying and rolling line, and full-type vacuum freezing and drying machine can be combined with a number of different specifications of production lines according to different batch output requirements, which not only realizes our company's high performance.Principal R & D ProductsThe production needs of the people can also be met.Customer-generation plus services.Demand. The core management team of the platform is composed of personnel who have many years of industry-level experience in the separation and purification of micro-fermentation, egg/enzyme, and ensure that the production of egg/enzyme products is operated in a compliant, controllable, and stable manner.

Service

Production generation service for R & D products

Features

From the combination of different batch production line.

Build

Standardized, high-quality, multi-variety, high-efficiency operation of the income-generating machine.

Standard

Products of stable quality in the demand of customers

2000 ㎡

DGrade purification area

Two

Mature art system

Micro-product Fermentation Art

Separation and Purification Art

Multiple sets

Different specifications of equipment

Fully-actuated fermentation system

Fully actuated dispensing system

Purification system

high velocity freezing machine

Full-hand washing, baking, pouring and rolling line

type vacuum freeze drying machine

……

Supporting quality inspection center

1 Establishment:DLevel Limit Laboratory and Positive Bacteria Laboratory

2 Establishment: For raw materials, intermediate products, finished products, a total of over100kinds of inspection methods

3 Establishment: microbiological test group, physical and chemical test group, biochemical activity test group3a professional group

The inspectors have received special inspection and verification training from a third party and have obtained the corresponding qualification certificates.

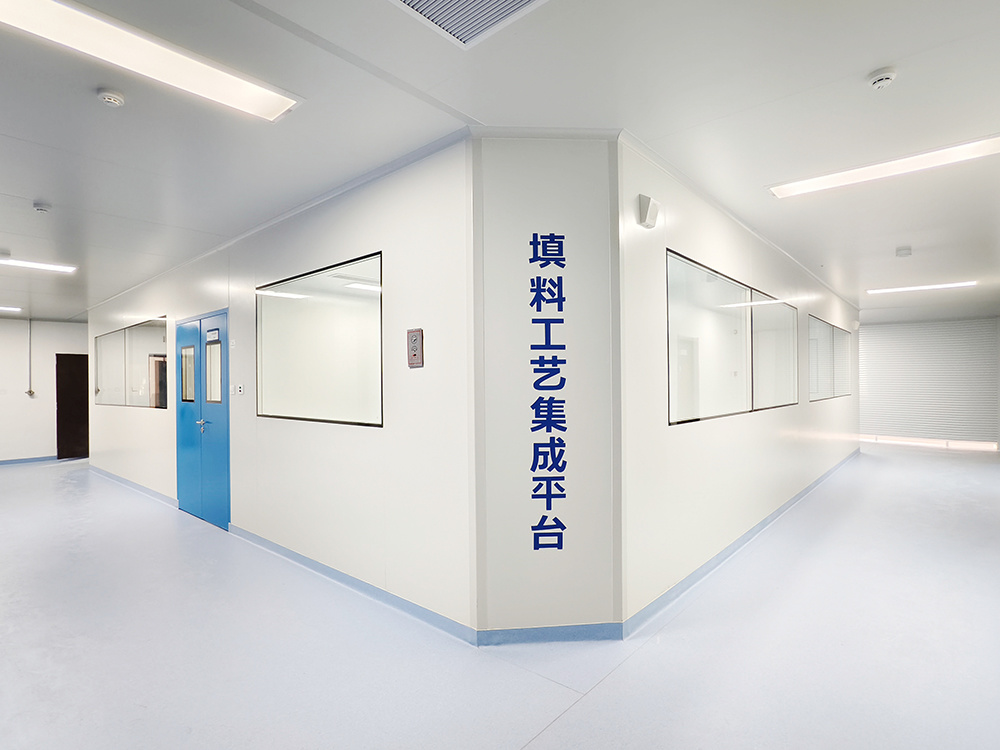

Filler Art Integration Platform

Introduction

Filler Art Integration Platform, Total Product600 ㎡to fully simulate120Tons of agarose gel filler project scale production model, integrated.DCSControl system, safety control system and environmental control system, the degree of automation is higher.80%, to achieve the monitoring, early warning and interlocking of the art process, full of safe production conditions, micro-production control conditions, quality stability conditions, from the high-quality art platform management level and efficiency.

R & D Center

Introduction

In the research and development of New Zealand, director Qian Yongchang always takes the lead, focusing on master and doctoral degrees. It is a multi-disciplinary, organic, complementary, professional and reasonable research and development team. The number of teams accounts for about 30% of the total number of the company. The research and development department has two departments: egg research and development department and filler research and development department. It has four platforms: egg design, micro-fermentation, filler design and development and efficacy evaluation. It has obtained a number of invention patents, undertaken a number of provincial, municipal, and district projects, won the Zhejiang Industry-University-Research Cooperation Promotion Award and other honors, and built a provincial post-doctoral work station and a provincial-level enterprise research and development center.